NEW PRODUCTS/DEVELOPED PRODUCTS

CNF Resin Composite STARCEL™

STARCEL™ (Cellulose Resin Composite)

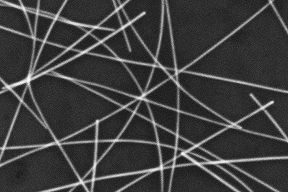

Cellulose nanofiber (CNF) is a nanofiber obtained by defibrillating cellulose to the nano-size and has superior features including low density, high strength, high elastic modulus and low thermal expansion.

CNF can be applied as reinforcing fibers for thermoplastic resins. CNF resin composite is expected to be applied to various fields such as automotive, home electric appliances and building materials.

- Product Series

- Application to foam materials

- Application to rubber materials

- Application to structural materials

- High heat resistance and high impact grade(NEW)

Product Series

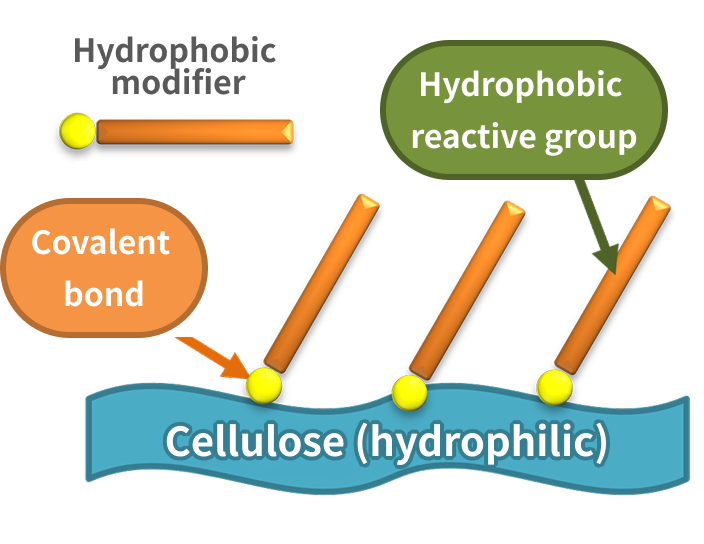

- The NC Series offers a lineup of products that contain various types of hydrophobic cellulose depending on the applications.

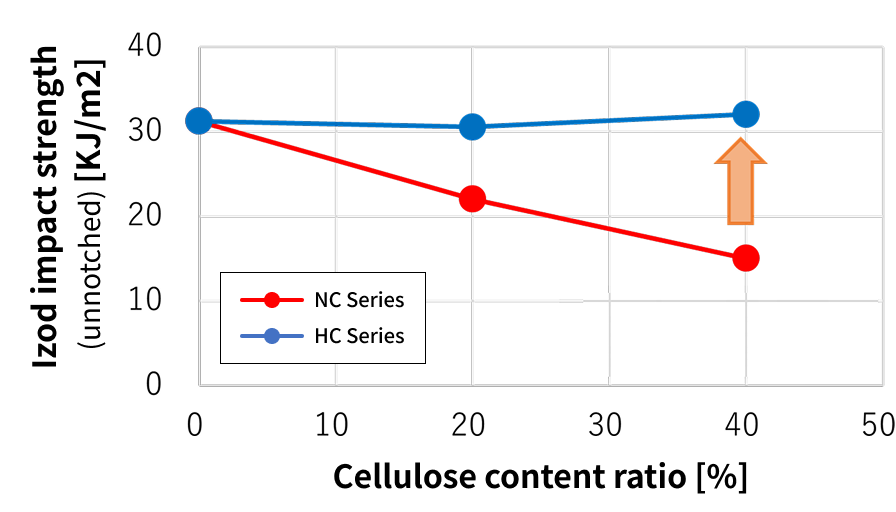

- In addition to the NC Series formulated with CNF in the base resin, we now offer the HC Series incorporating cellulose microfiber.

| Series | Cellulose | Surface | Primary applications | Benefit |

|---|---|---|---|---|

| NC Series (hard) | CNF | Hydrophobization | Structural materials | High elasticity, low linear thermal expansion |

| NC series (soft/foam) | CNF | Hydrophobization/reactivity | Foam materials, rubber materials, structural materials | Integration with polymers |

| HC Series | Microfiber | Hydrophobization | Structural materials | High thermal resistance, shock resistance |

*1: Our press release: CNF Composite Material STARCEL™ Receives EcoPro Award

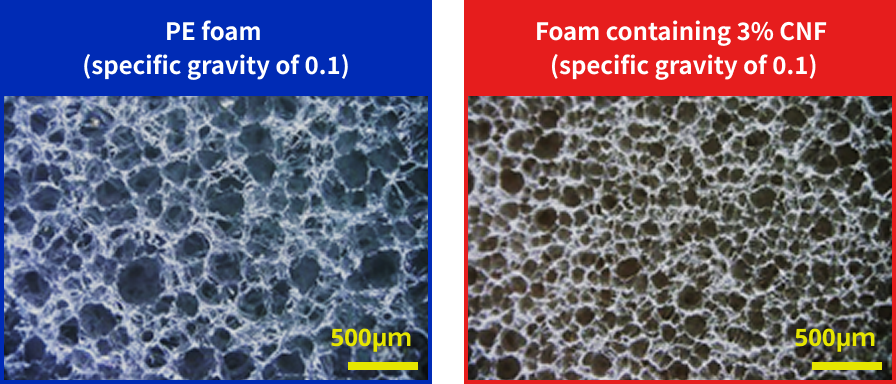

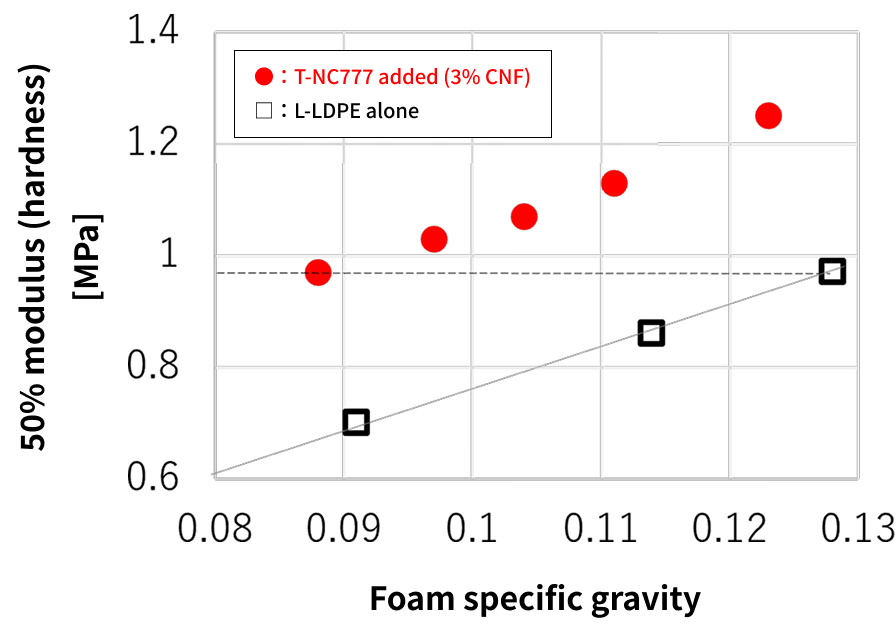

Application to foam materials

(NC Series, foams, cushioning materials, sealing materials, etc.)

- The bubble diameter shrinks, causing the foam to become denser, and the CNF reinforces the bubble walls to impart hardness and durability to the foam.

- This allows the expansion ratio to be increased while maintaining the hardness of the foam, making the material lighter.

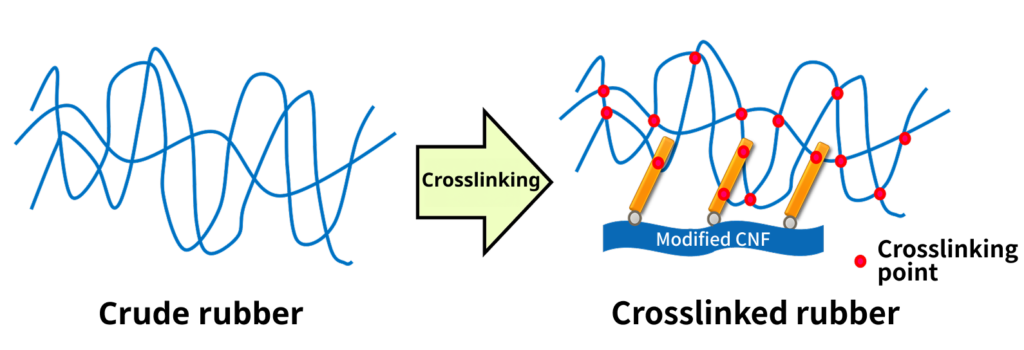

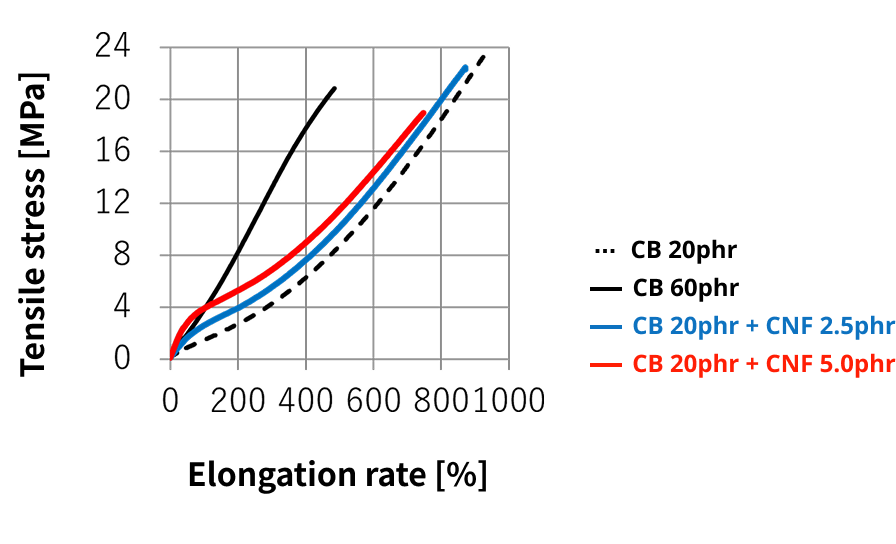

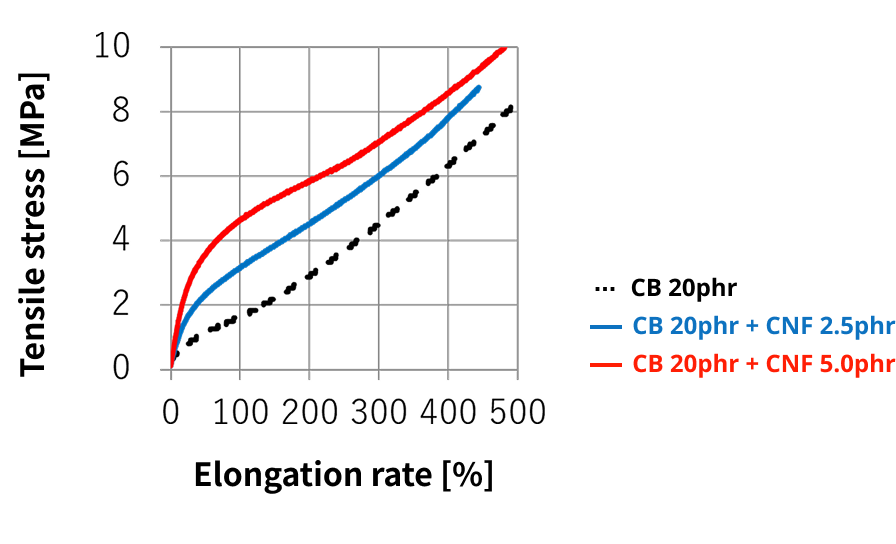

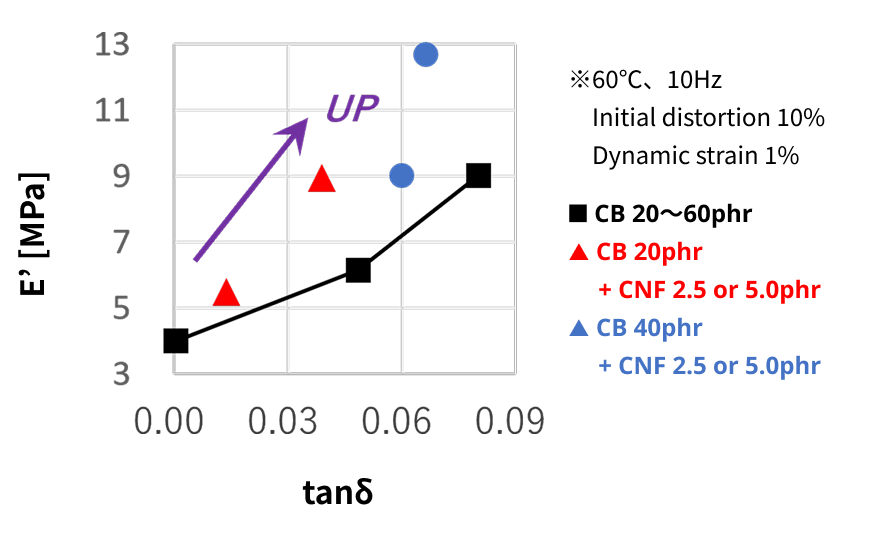

Application to rubber materials

(NC Series, tires, belts, hoses, etc.)

- Addition of a small amount to carbon black (CB) compounded rubber imparts hardness.

- This enables the design of compounds with high hardness and low tan δ.

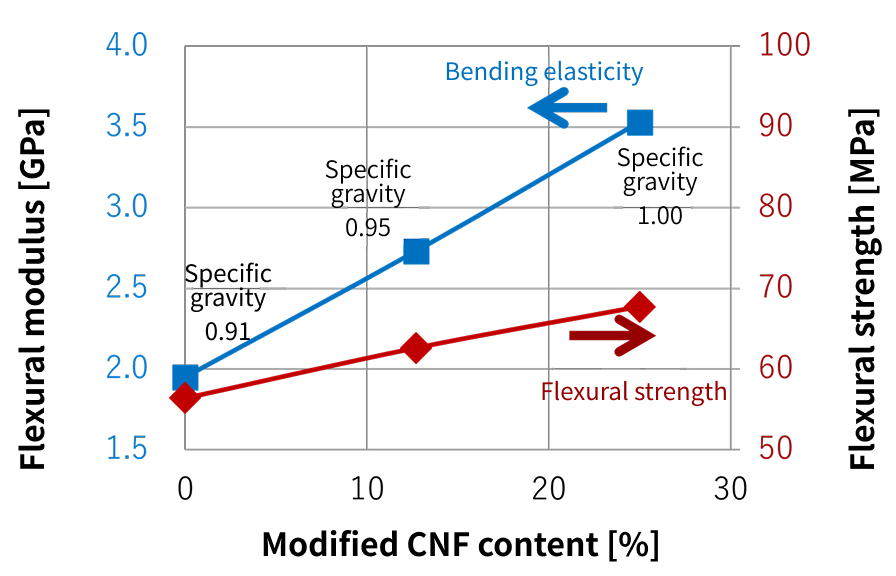

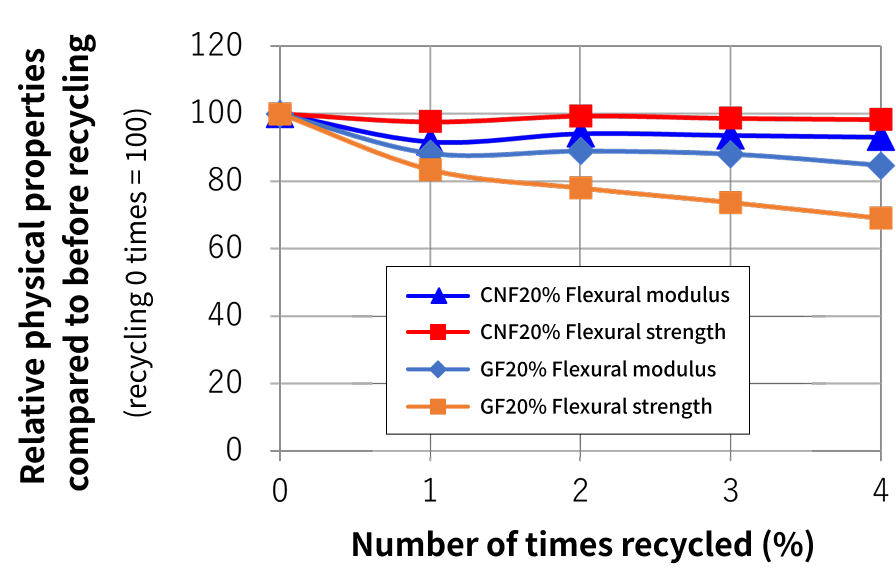

Application to structural materials

(NC Series, automobiles, household appliances, building materials, etc.)

- Imparts hardness and strength to resin

- Exhibits thixotropic properties and enables injection molding even at high concentrations.

- Offers excellent recyclability.

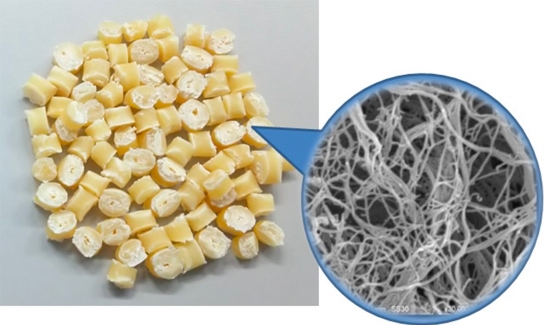

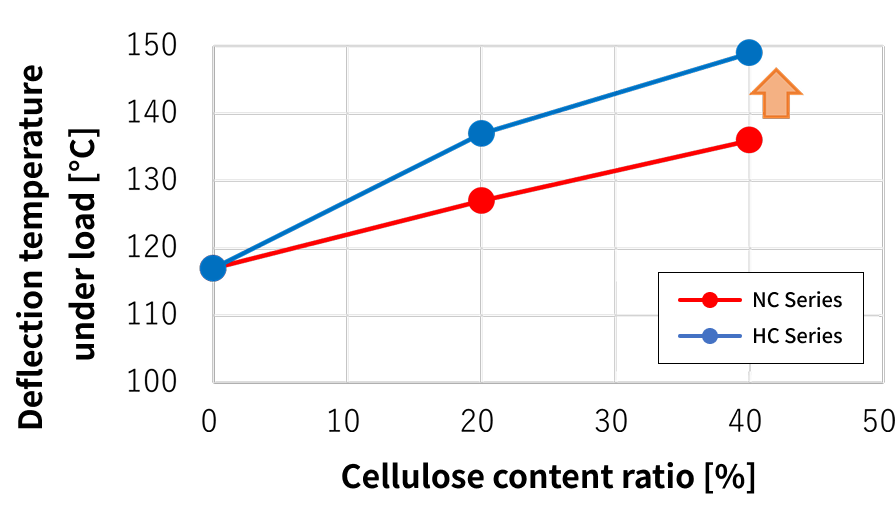

High heat resistance and high impact grade HC Series

(cellulose microfiber composite resin)

- The pellets contain cellulose microfibers with nano-sized surfaces.

- Lighter colored molded products are possible than with the NC Series.

- Offers strong heat resistance (deflection temperature under load) and impact properties.

We are currently working with our customers to develop a wide range of practical applications for these products.

*These products are currently under development. For more details, contact us using the link below.