NEW PRODUCTS/DEVELOPED PRODUCTS

Biofilm Control Agents

<Biofilm>

A biofilm is a viscous deposit made up of bacteria. Biofilms cause problems in various water environments and are difficult to prevent and control.

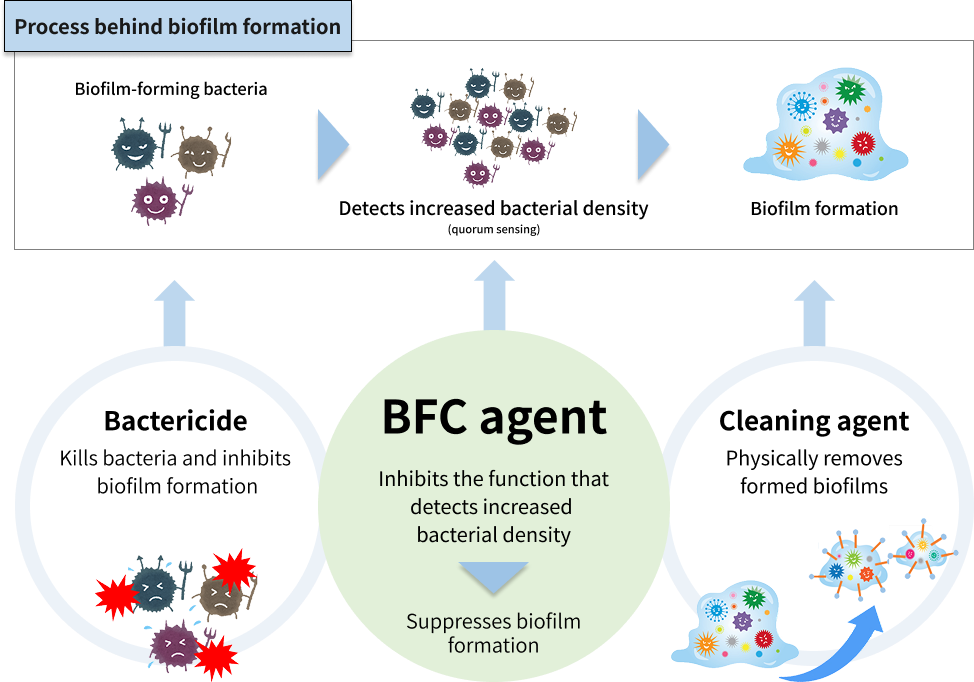

Biofilm control agents (BFC agents) are highly effective in preventing the formation of and removing existing biofilms. These agents work through a novel mechanism of action that targets the bacterial metabolic pathways to inhibit biofilm formation.

For example, BFC agents are effective against biofilms in reverse osmosis membranes and chemical dilution tanks (see examples of BFC agent applications).

<Examples of expected applications>

- Biofilm control solutions for cooling towers, hot springs, and wet areas in nursing care facilities. (prevention of Legionella proliferation

- Biofilm inhibiting effect imparted through coating or incorporation into components

- Prevention and control of biofilm-associated bacterial infections

- Suitable for any environment where biofilms may develop: RO membranes, medical devices, food and beverage equipment, household wet areas, and oral care applications

- BFC agent

- The mechanisms of action of BFC agents

- Differences from existing countermeasures

- Effectiveness of BFC agents

- Examples of BFC agent applications

- BFC agent composed of food additives

BFC agent

BR Series

- This is a new type of product whose biofilm formation inhibitory effect differs from that of fungicides.

- Non-sterilizing, non-oxidizing, and can be used at a neutral pH, meaning it is highly safe to handle and will not cause parts to deteriorate.

- Effective in a wide range of pH levels.

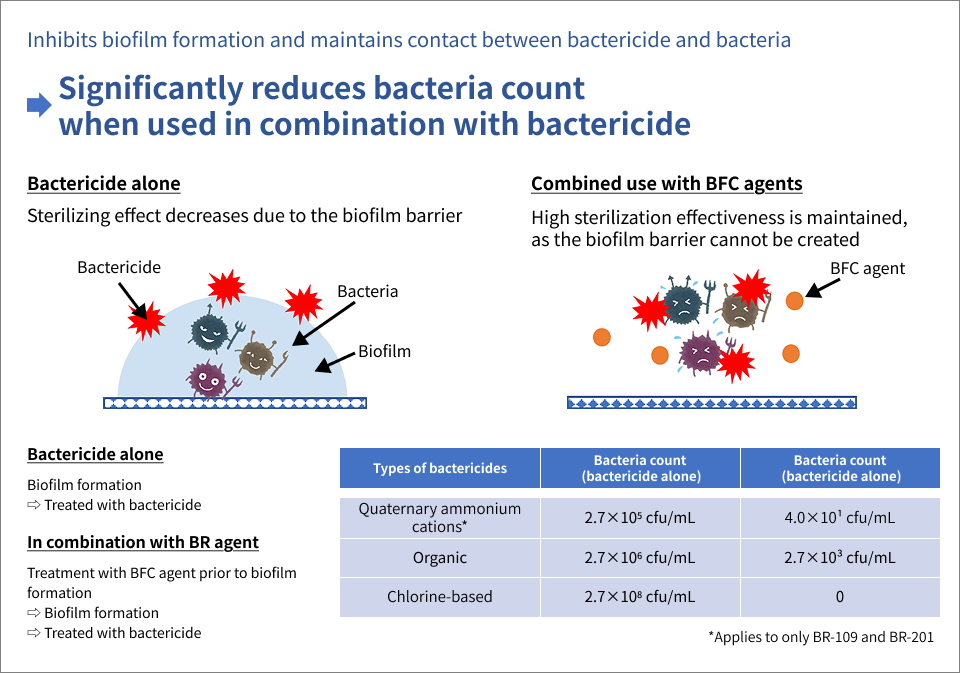

- Combined use with bactericides enhances the duration of antimicrobial effects.

| Item | Effect | Appearance | Usage concentration [%](*1) | Viscosity [mPa・s] | Product pH | Notes |

|---|---|---|---|---|---|---|

| BR-109 | Quorum sensing inhibition | Light brown to brown in color Transparent liquid | ~0.35 | 15~30 | 5.8~8.0 | |

| BR-110 | Inhibition of quorum sensing and removal of biofilms | Light brown to brown in color Transparent liquid | ~0.35 | 15~30 | 6.0~7.0 | |

| BR-201 | Quorum sensing inhibition | Colorless to light yellow in color Transparent liquid | ~0.27 | ~25 | 2.5~4.0 | Composed of food additives approved by FDA and MHLW |

| BR-202 | Inhibition of quorum sensing and removal of biofilms | Colorless to light yellow in color Transparent liquid | ~0.22 | ~25 | 3.5~5.0 | Composed of food additives approved by FDA |

(*2: BR-109 precipitates at 6°C or below, and BR-110 at 0°C or below. If turbidity or precipitation is observed, heat to approx. 40°C and agitate for one hour to dissolve before using.)

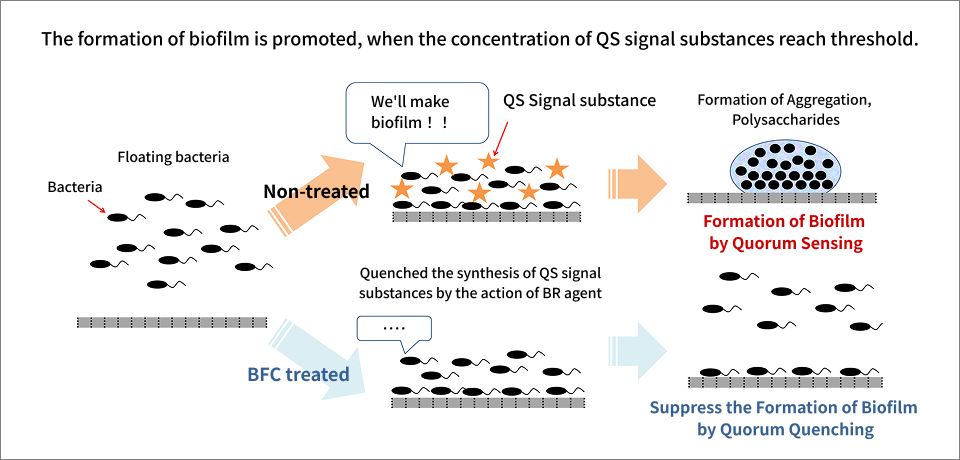

The mechanisms of action of BFC agents

①Inhibition of biofilm formation (all product numbers)

BFC agents inhibit biofilm formation mediated by extracellular signals (quorum sensing) and block the bacterial biofilm formation mechanism (non-bactericidal).

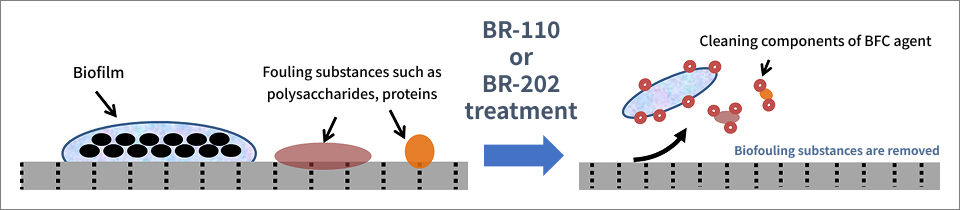

②Removal of biofilms (BR-110, BR-202)

Accumulated biofilms and fouling substances (*3) are efficiently removed by selected cleaning components that are effective in dispersing biofilms.

(*3: Polysaccharides, proteins, etc., that cause membrane clogging)

Differences from existing countermeasures

Effectiveness of BFC agents

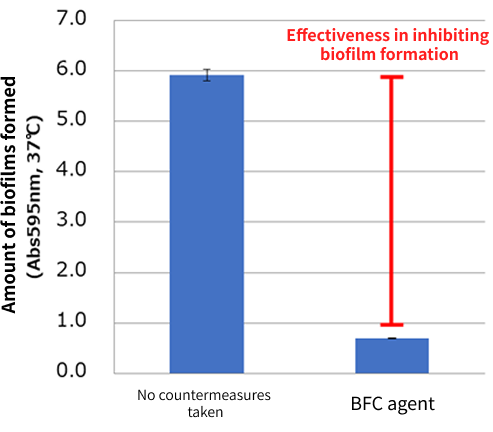

①Inhibition of biofilm formation (all product numbers)

・Biofilm-forming bacteria (Pseudomonas sp.) are cultured in a medium containing BFC agents.

・After culturing, biofilms formed on the walls of the culture plate wells are dyed with crystal violet, and the degree of staining is compared to cultures with no countermeasures taken to calculate the inhibition rate.

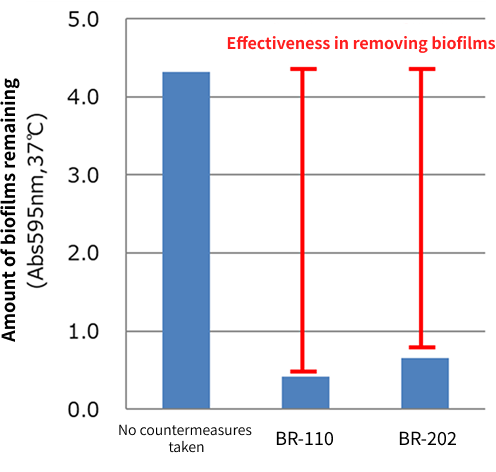

②Removal of biofilms (BR-110, BR-202)

・Biofilm-forming bacteria (Pseudomonas sp.) are cultured and biofilms are allowed to form on the walls of the culture plate wells.

・BR-110 or BR-202 are added to the culture solution and shaken.

・Biofilms remaining on the walls of the wells are dyed with crystal violet, and the degree of staining is compared to cultures with no countermeasures taken to calculate the removal rate.

③When used in combination with bactericide

Examples of BFC agent applications

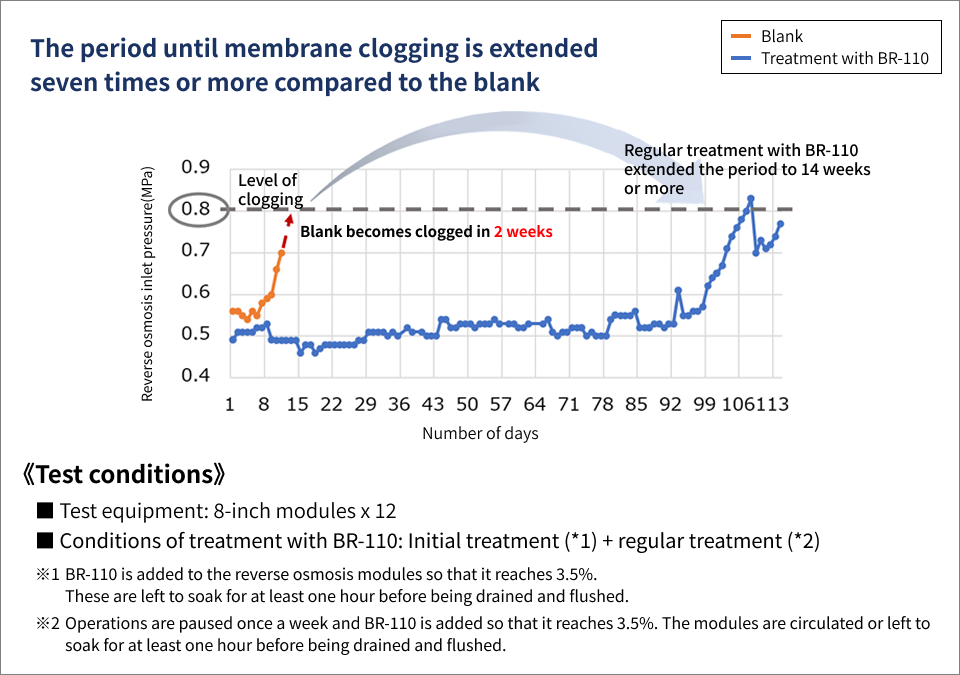

①Reverse osmosis membrane clogging inhibition (BR-110)

Due to membrane degradation concerns, reverse osmosis (RO) membranes cannot be treated with hypochlorous acid or other bactericides, making biofilm-related membrane fouling a critical issue.

Field testing demonstrated that BR-110 treatment extended the membrane fouling interval from two weeks to more than fourteen weeks in bactericide-free desalination operations.

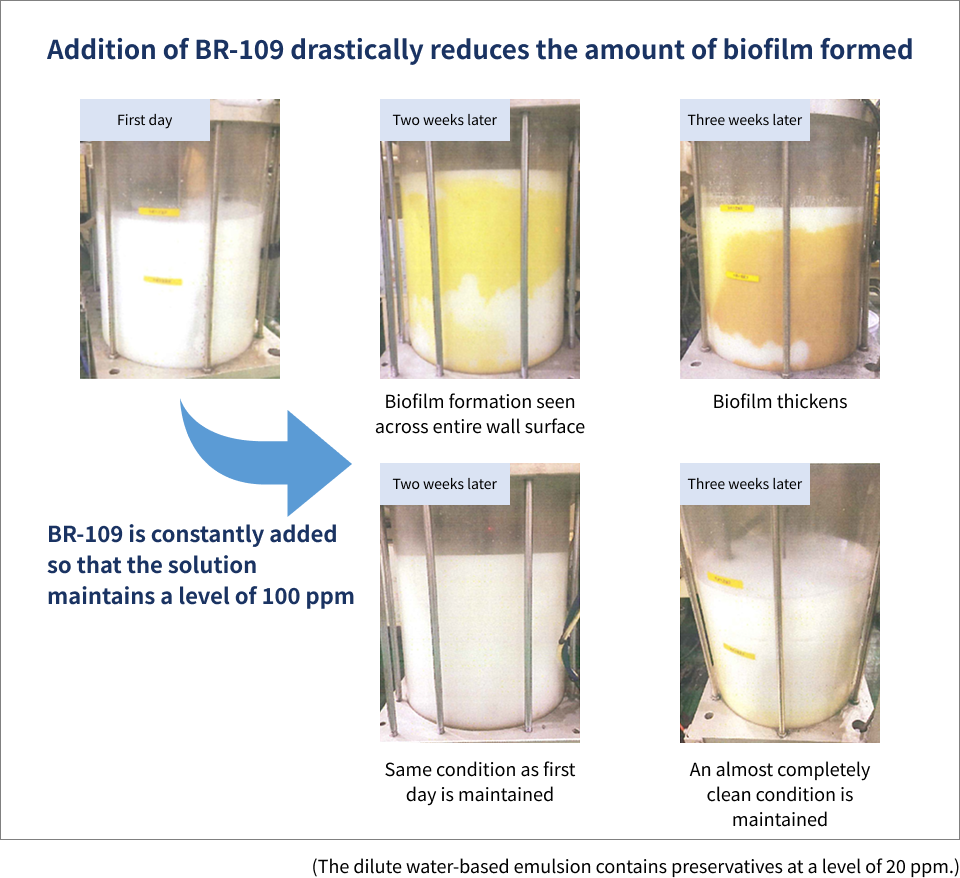

②Biofilm inhibition in chemical dilution tanks (BR-109)

While biofilms typically covered the entire wall surface of water-based emulsion dilution tanks within two weeks, the addition of BR-109 at 100 ppm significantly suppressed biofilm formation.

③Countermeasures against biofilms in wet settings (pdf)

④Countermeasures against biofilms in oral cavities (BR-201) (pdf)

BFC agent composed of food additives

Products made up of food additives listed by the US Food and Drug Administration (FDA)

Suitable for applications requiring stringent safety standards, such as food processing plants and beverage facilities.

See here for more details.

| FDA category | Category under relevant Japanese legislation | |

|---|---|---|

| BR-201(BR-109 equivalent) | 21 CFR 172、184 21 CFR 175~178 | Food additives |

| BR-202(BR-110 equivalent) | 21 CFR 172、184 21 CFR 175~178 | ― |

21 CFR 175~178:Indirect food additives

We are currently working with our customers to develop a wide range of practical applications for these products.

*These products are currently under development. For more details, contact us using the link below.